- Contacts:Mr.Wu

- Telephone:+86-021-20233905

- E-mail:wuqidong0425@clean-air-edge.com / 1014998957@qq.com

- Address:Room 304, 199 Jiangkai Road,Minhang District,Shanghai,China

Product Introduction

Compressor

◆Radial and axial double flexible design, more optimized axial floating seal design, lifting efficiency.

◆R410A Refrigerant , high efficiency, long bearing life.

◆Direct drive, greatly reduce with less moving par t s ,improve the mechanical efficiency

◆Accurate load calculation,built-in seal cover design to reduce operating noise

◆Built in multiple protection to ensure reliable operation of the compressor.

High efficiency heat exchanger

◆Using 316 stainless steel plate.

◆Compact structure, less weight and lowpressure drop, high heat transfer efficiency.

◆Patented design of two phase refrigerantdistributor, to ensure that the refrigerant in

the two-phase area evenly distributed toeach flow channel.

Electronic expansion valve

◆The control system automatically calculates the optimal target value and makes a quick response to the dynamic setting.

◆Precise adjustment of refrigerant flow rate accordingto system load.

◆It is reliable to ensure the high unit operating efficiency at different working condition

Green

◆Utilizing new environmental friendly refrigerant R410A.

◆Good heat transfer performance, no CO2, PM2.5 emissions, no pollution to the environment.

Controller

◆Touch screen.

◆Utilizing multiple defensive control logic, protect system and compressor.

◆Using PID control logic to control the compressor's loading and unloading, and the electronic expansion valve’opening.

◆Designed with even compressor wear time control to extend the compressor lifespan.

◆Available with centralized group control, compatible with BMS connection.Unit designed various protections such as high pressure, low pressure, lack of phase,

◆reverse phase, flow, overload, overheating, antifreeze, high load protection, etc.

Easy to operate

◆Each unit is fully run tested with water at factory before shipping, only water and electrical cable are required to be connected at site

◆Each unit is fully run tested with water at factory before shipping, only water and electrical cable are required to be connected at site

◆New touch screen control, friendly man-machine interface, graphic menu management, intelligent control mode, easy to operate.

◆Automatic microprocessor control, all load adjustments are

performed by CPU to realize operating without human intervention.

Provide a variety of control functions, alarm and saving information,

◆it is easy for customer to know the unit operation status.

Rich Options

◆Top Line series offers numerous options to meet customer's

different requirements.

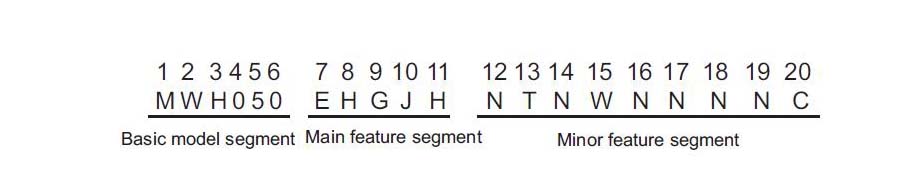

Nomenclature

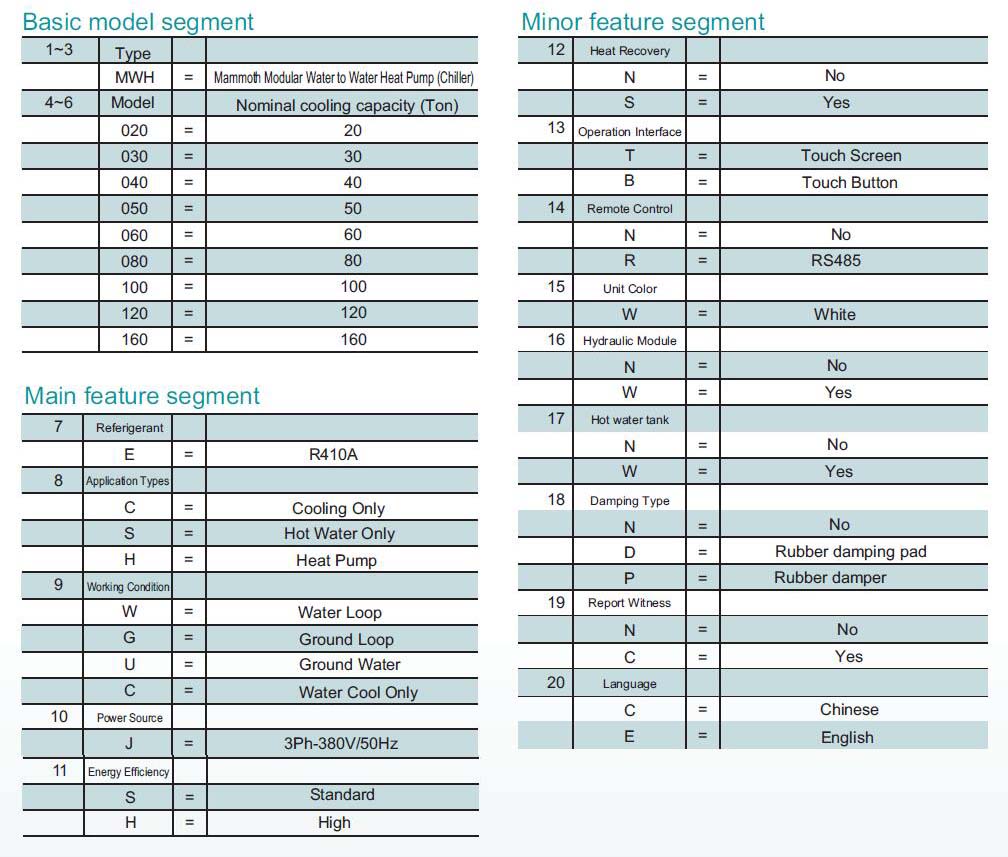

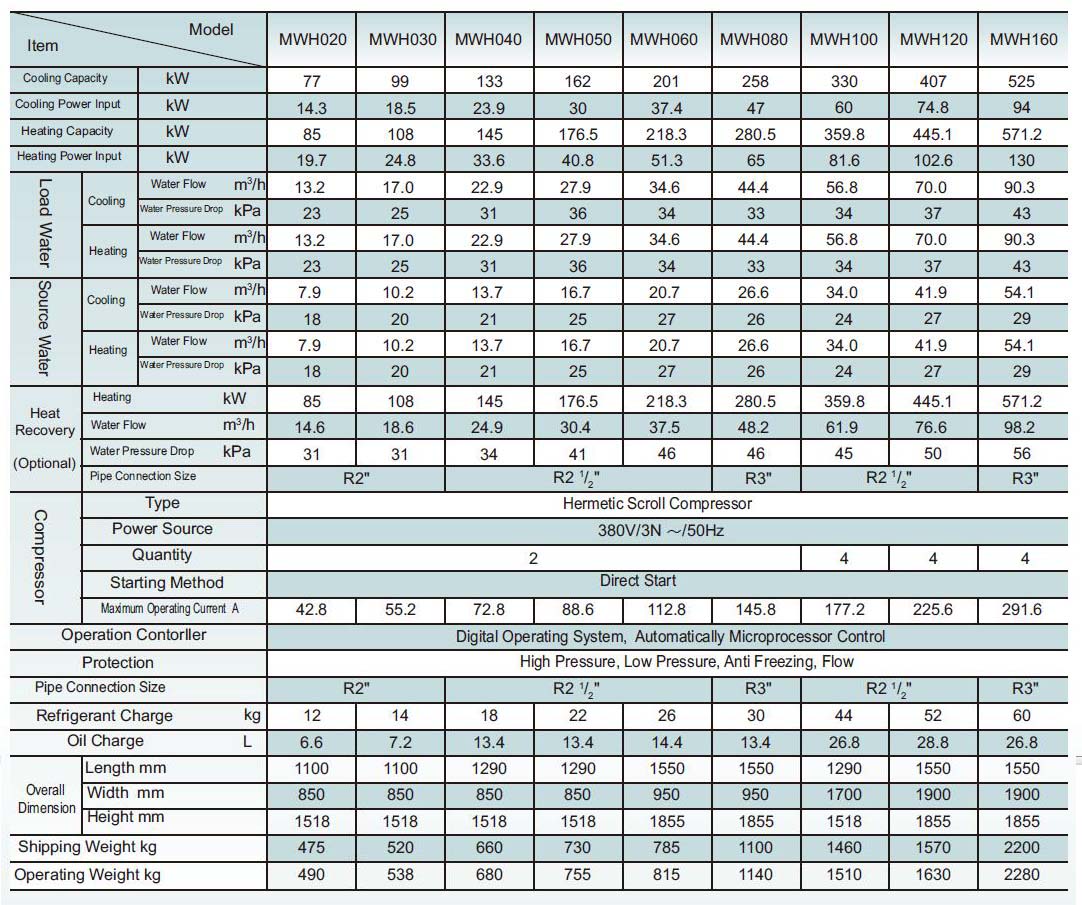

Standard Efficiency Water to Water Heat Pump Technical Specification (Water Loop)

Note:

1. Standard unit water side design pressure is 1.0MPa, If any other request on pressure

2. Cooling capacity is based on 30℃ entering source water and 7℃ leaving load water;

Heating capacity is based on 20℃ entering source water and 45℃ leaving load water;

Heating recovery capacity is based on 7℃ leaving load water and 40℃/45℃ entering/leaving domestic hot water.

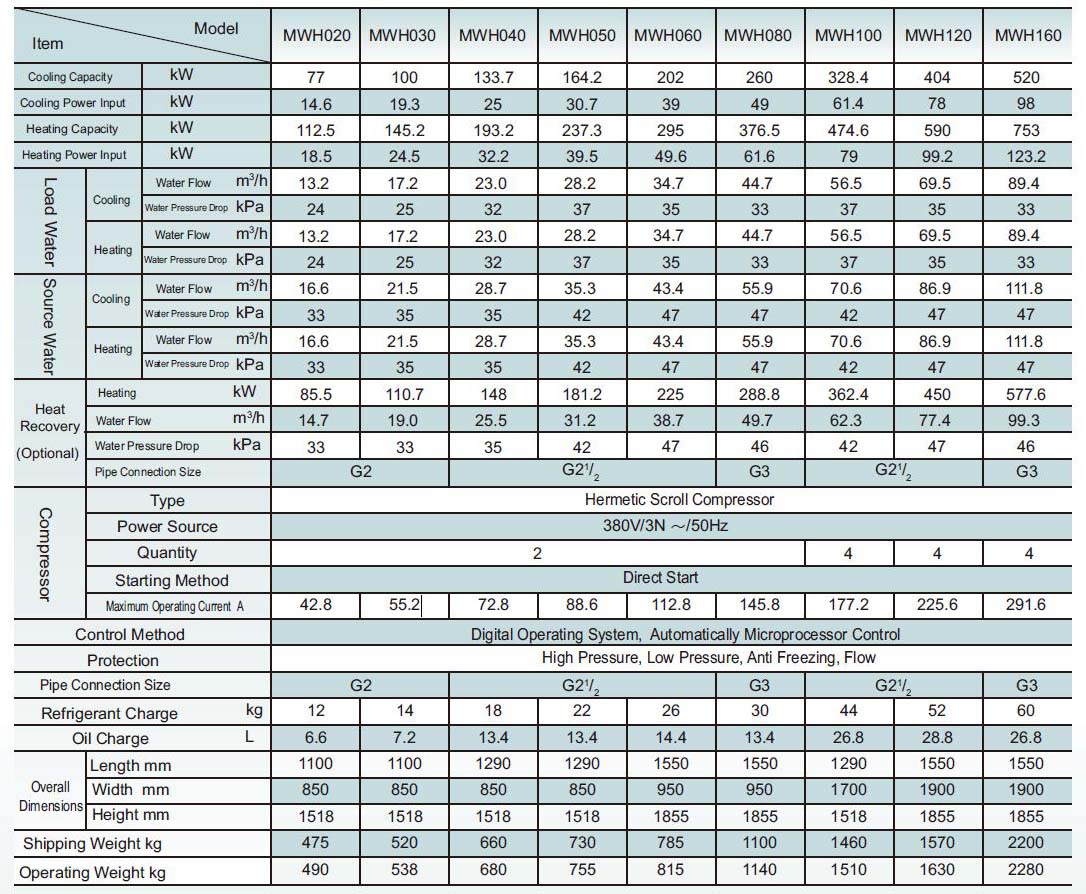

Standard Efficiency Water to Water Heat Pump Technical Specification (Geotheraml)

Note:

1. Standard unit water side design pressure is 1.0MPa, If any other request on pressure please contact us.

2. Cooling capacity is based on 25℃ entering source water and 7℃ leaving load water;

Heating capacity is based on 10℃ entering source water and 45℃ leaving load water;

Heating recovery capacity is based on 7℃ leaving load water and 40℃/45℃ entering/leaving domestic hot water.

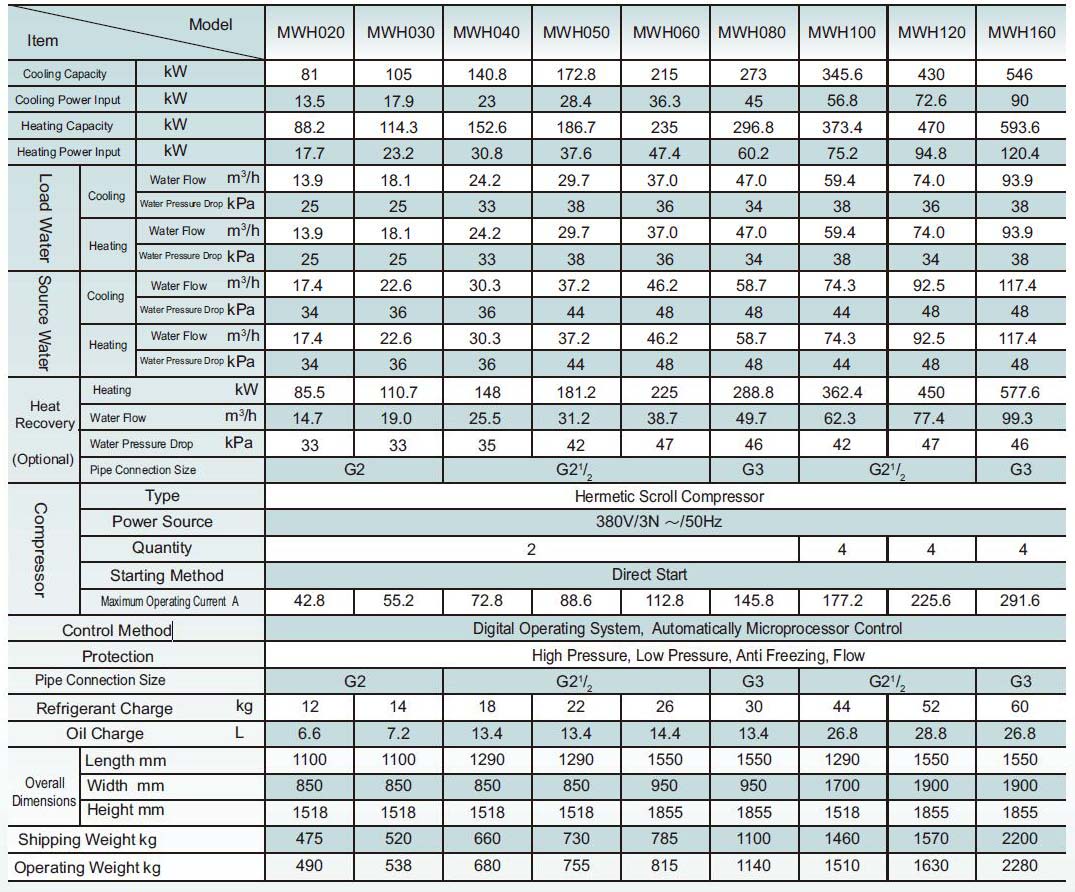

Standard Efficiency Water to Water Heat Pump Technical Specification (Ground water)

Note:

1. Standard unit water side design pressure is 1.0MPa, If any other request on pressure please contact us.

2. Cooling capacity is based on 18℃ entering source water and 7℃ leaving load water;

Heating capacity is based on 15℃ entering source water and 45℃ leaving load water;

Heating recovery capacity is based on 7℃ leaving load water and 40℃/45℃ entering/leaving domestic hot water.

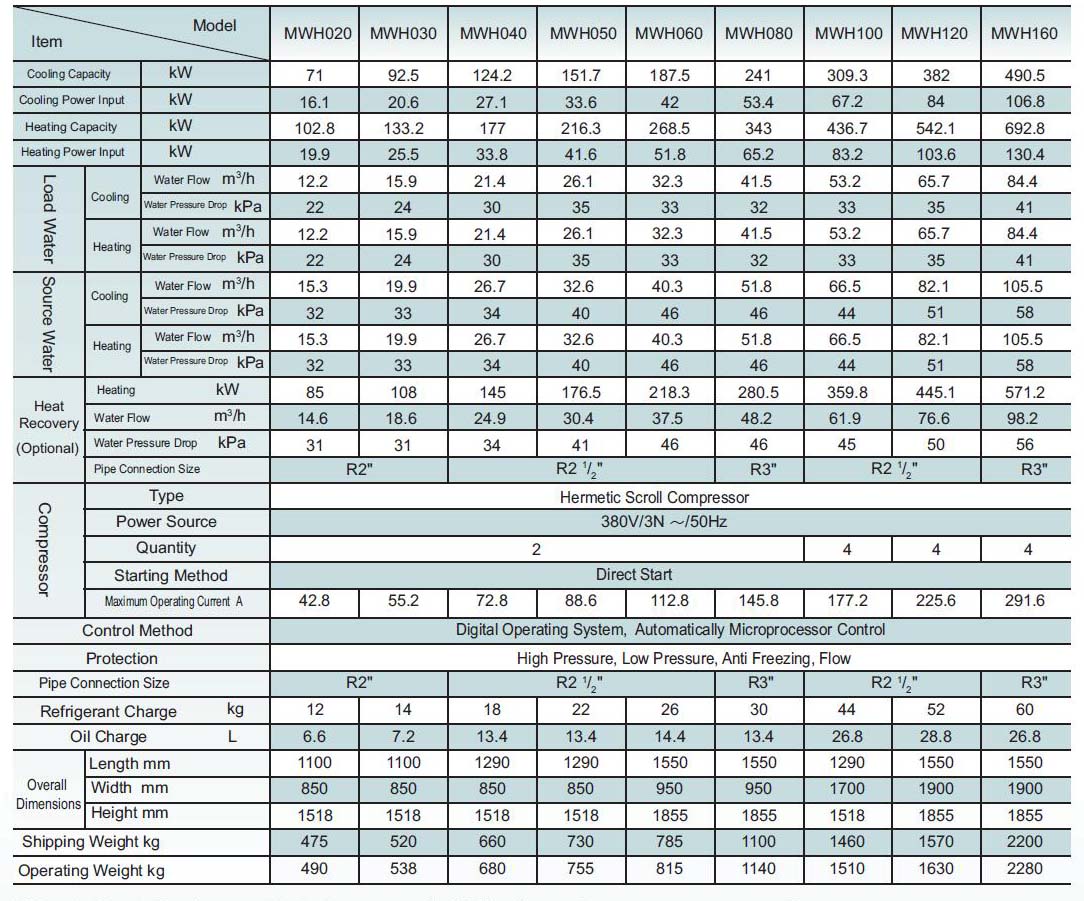

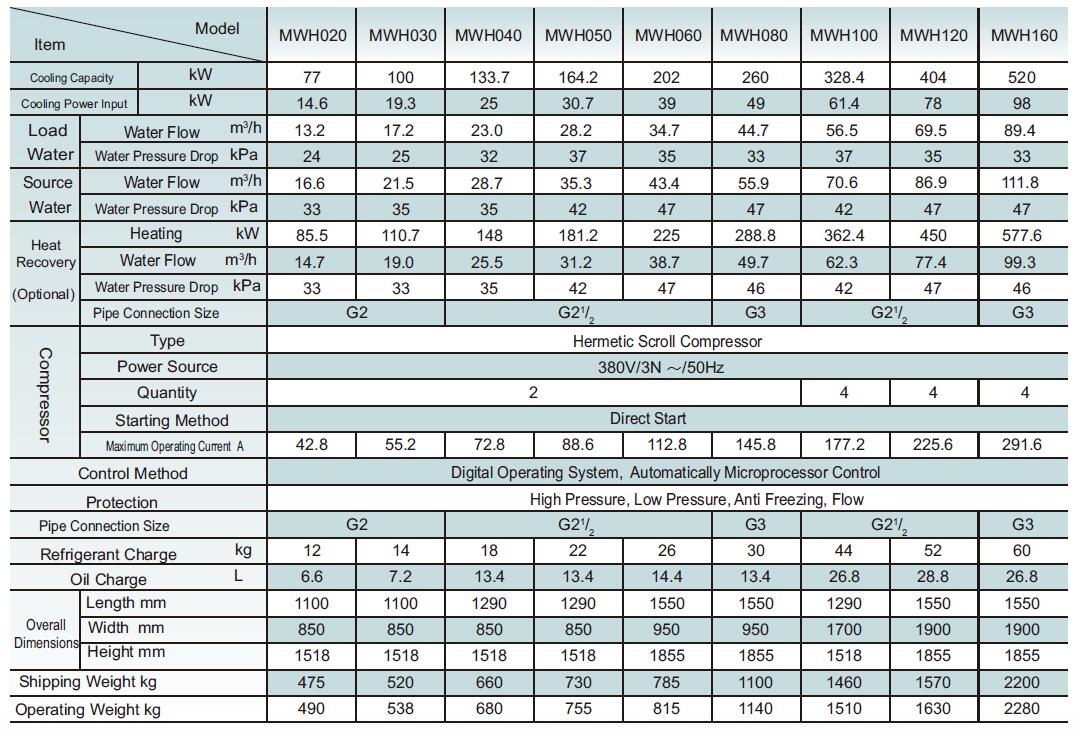

High Efficiency Water to Water Heat Pump Technical Specification (Water Loop)

Note:

1. Standard unit water side design pressure is 1.0MPa, If any other request on pressure please contact us.

2. Cooling capacity is based on 30℃ entering source water and 7℃ leaving load water;

Heating capacity is based on 20℃ entering source water and 45℃ leaving load water;

Heating recovery capacity is based on 7℃ leaving load water and 40℃/45℃ entering/leaving domestic hot water.

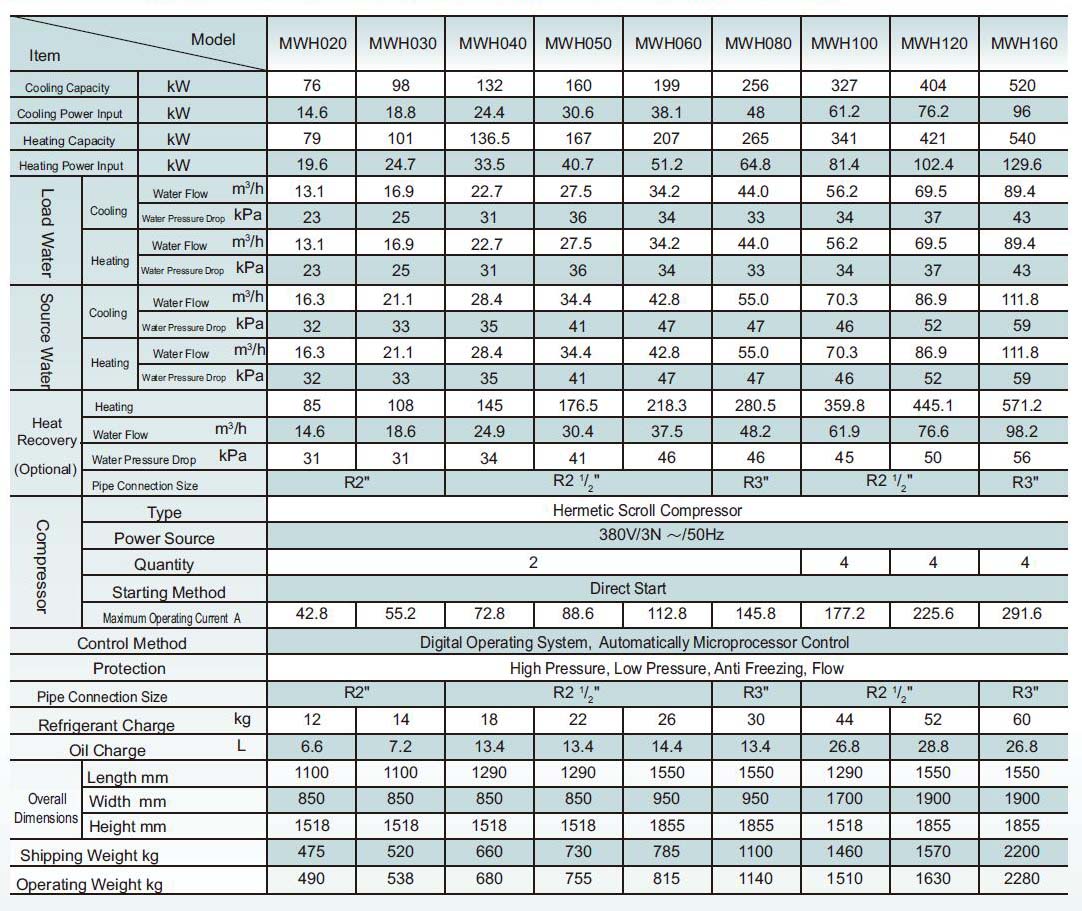

High Efficiency Water to Water Heat Pump Technical Specification (Geothermal)

Note:

1. Standard unit water side design pressure is 1.0MPa, If any other request on pressure please contact us.

2. Cooling capacity is based on 25℃ entering source water and 7℃ leaving load water;

Heating capacity is based on 10℃ entering source water and 45℃ leaving load water;

Heating recovery capacity is based on 7℃ leaving load water and 40℃/45℃ entering/leaving domestic hot water.

High Efficiency Water to Water Heat Pump Technical Specification (Cooling Only)

Note:

1. Standard unit water side design pressure is 1.0MPa, If any other request on pressure please contact us.

2. Cooling capacity is based on 30℃ entering source water and 7℃ leaving load water;

Heating recovery capacity is based on 7℃ leaving load water and 40℃/45℃ entering/leaving domestic hot water;

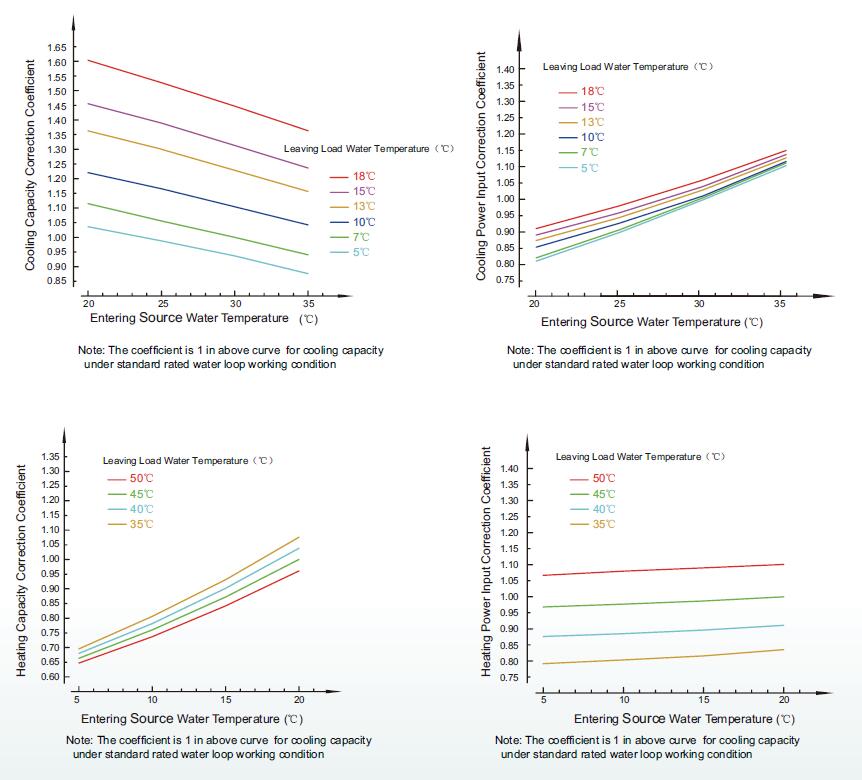

Water Loop/Cooling Only Correction Table

Notes:

1.Graph data are for reference only, variable condition parameters will be slightly different for different model;

2.The unit operation range should be considered when correction is calculated for different working condition, see page 16, table of Operation Limits.

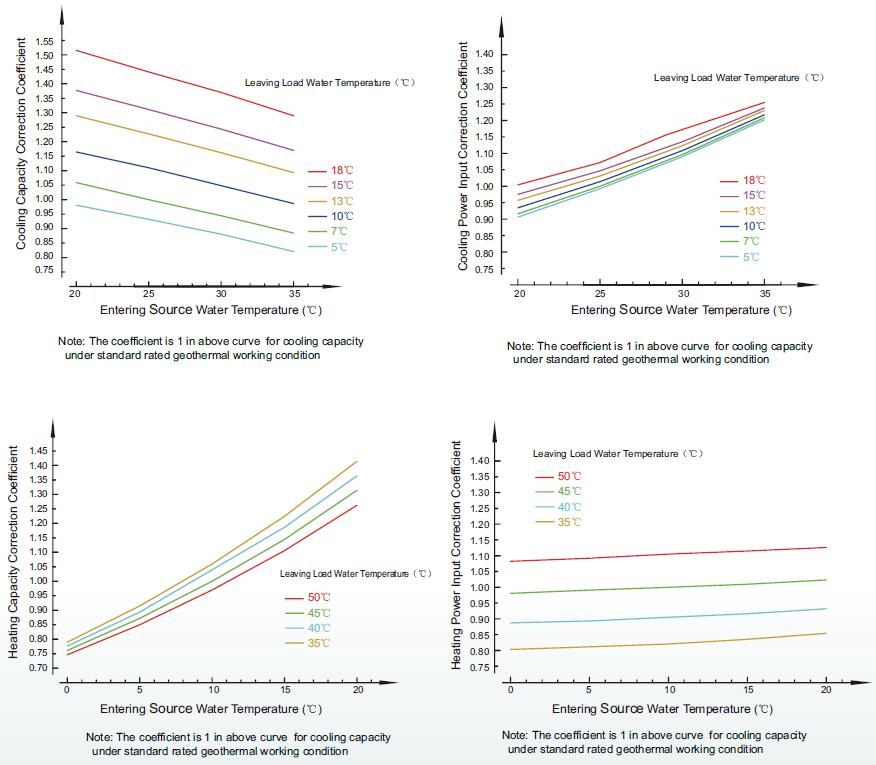

Geothermal Condition Correction Table

Notes:

1.Graph data are for reference only, variable condition parameters will be slightly different for different model;

2.The unit operation range should be considered when correction is calculated for different working condition, see page 16, table of Operation Limits.

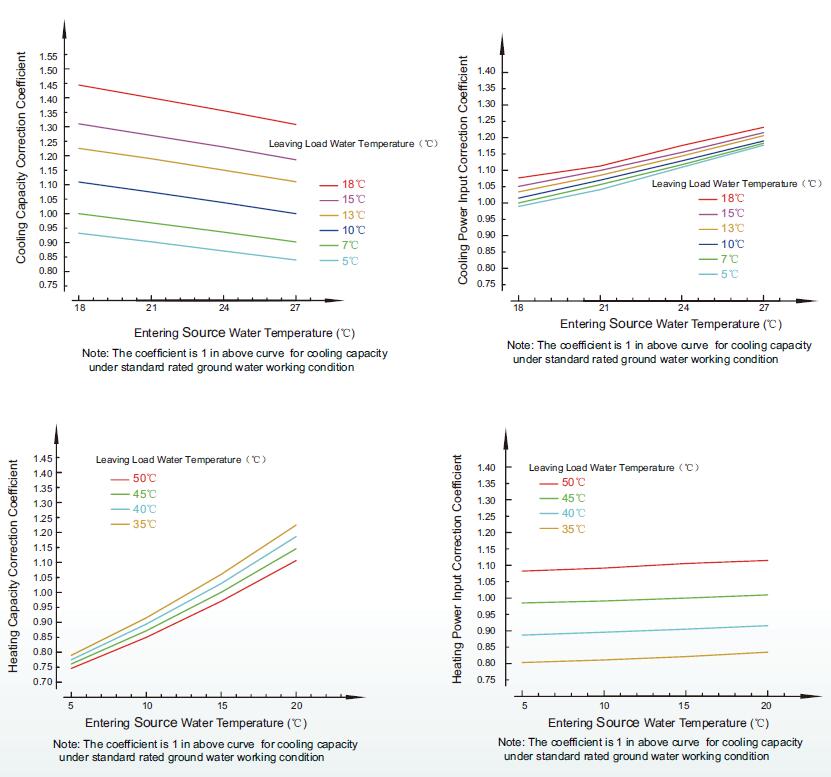

Ground Water Condition Correction Table

Notes:

1.Graph data are for reference only, variable condition parameters will be slightly different for different model;1.Graph data are for reference only, variable condition parameters will be slightly different for different model;

2.The unit operation range should be considered when correction is calculated for different working condition, see page 16,table of Operation Limits.